Ultimate Guide to Profile Blanking

Estimated reading time: 18 minutes

Profiles are one of the important raw materials for sheet metal components. The common profiles used in sheet metal are angles, channels, I-beams and rounds, flat bars, tubes, etc. According to the different processing equipment of the production enterprises, there are various methods for cutting different profile blanking, among which the most widely used ones are: sawing blanking and punching blanking.

Profile sawing

Sawing is the processing method to cut off the material or the kerf and groove of the workpiece through the cutting movement of the saw teeth, and it can be divided into manual sawing and mechanical sawing according to the different ways of applying force during sawing movement; it can be divided into the band saw, disc saw and friction saw according to the different kinds of saw blades used.

Manual sawing

Manual sawing is one of the ways to split the metal material (or workpiece) by hand sawing, and the hand saw is mainly composed of two parts: the saw bow and the saw blade.

The saw bow is used to tension the saw blade. There are two types of fixed and adjustable, as shown in the figure below. The saw blade is generally made of carburized steel cold-rolled but also made of carbon tool steel or alloy steel, hardened by heat treatment. Commonly used saw blade is 300 mm long (the length between the two installation holes), 12 mm wide, 0.8 mm thick this kind.

1. The choice of saw teeth

Manual sawing the most important tool is the saw teeth, the tooth pitch is determined by the number of teeth per inch (25.4 mm) length, divided into coarse, medium, and fine 3 kinds. Different types of saw teeth can be selected to complete the cutting of various material profiles, pipe fittings, plate material under the material. The choice of tooth type is based on the mechanical properties and thickness of the material to be sawed (see the table below).

Types of saw teeth and selection range

| Serrated type | Number of serrationsn(n/25.4mm) | Application Scope |

| Coarse Medium Fine | 14~18 22~24 32 | Sawing soft steel, brass, aluminum, pure copper, cast iron, plastic, and other materials Sawing medium-hard steel, thick-walled copper tubes Thin sheet metal, thin-walled tubes, and hard materials |

The ordinary saw blade is best used for medium hardness of the following material sawing, when using a fine tooth saw blade sawing hard material, or use coated diamond saw blade sawing glass, ceramics, hardened steel, start sawing when using the front end of the saw blade against the edge of a face, and material surface tilt angle α is about 15 °, and ensure that there are three teeth at the same time contact with the material. In order to make the size of the starting saw accurate, you can first use your left thumb to lean on the side of the saw blade for guidance, light pressure for a short distance back and forth push and pull, so as to make the saw blade easy to eat into, see the figure below.

2. Sawing methods for various workpieces

The sawing methods are different for sawing different profiles, or for sawing the same profile with different requirements.

- Bar sawing

If the required sawing bar sawing surface is flat, it should be sawed continuously from the beginning to the end. If the requirement is not high, the direction can be changed several times when sawing, so that the bar material can be sawed again after a certain angle, so that it is easy to saw into because the sawing surface becomes smaller, and the efficiency can be improved.

- Pipe sawing

Sawing pipe can not always saw to the end, otherwise, the teeth are easy to be stuck and chipped, the correct sawing method is: when the tube material is sawed through, the tube material along the direction of the push saw to turn an appropriate angle and then saw, so that the tube more than a few directions, each direction saw through to the inner wall can be.

- Sawing of thin plate material

Sawing thin plate material should be as far as possible from the wide side of the saw down, when only from the narrow side of the plate material saw down, available two boards clamping, the wood together, to avoid the saw teeth being hooked, but also to improve the rigidity of the plate material, so that the sawing does not chatter, as shown in the following figure (a). You can also clamp the thin board material directly on the bench vise, and use the hand saw for lateral diagonal push sawing so that the number of teeth in contact with the thin board increases to avoid chipping of the saw teeth, as shown in the figure below (b).

- Sawing of flat steel

Sawing flat steel, in order to get a neat seam, should be from the wider side of the flat material under the saw, so that the sawing depth is shallow, the saw blade does not jam or damage the teeth and saw blade.

- Angle and channel sawing

Sawing angle and channel steel should be used from two sides (or three sides), but each saw off a plane, must change the clamping position.

mechanical sawing

In addition to manual sawing, commonly used sawing tools are: hand saw, high and low-speed circular saw, friction saw, metal band saw and bow pendulum saw are generally mechanical sawing, the following figure (a), (b), (c) are commonly used hand-held wind saw, grinding wheel cutting machine and bow sawing machine and other sawing equipment shapes.

The above-mentioned sawing equipment can be used not only for the undercutting of profiles but also for the cutting of other metal materials. When sawing materials, it can generally be selected for use according to the nature and size of the sawed materials.

Punching and cutting of profiles

In production, the cutting of angle steel, channel steel, and other profiles and special profiles is generally guaranteed by mechanical processing methods such as sawing or milling, but when the production batch of parts is larger and there are more varieties, the traditional mechanical processing method is not conducive to the improvement of economic efficiency due to the low production efficiency, and more consideration is given to profile punching die processing.

The characteristics of profile blanking processing

Most of the profile processing is single-sided punching, the punching force is unbalanced, and both the material and the punch are subject to offset force, which easily causes the punch to break or deflect the material and crack. While the die is subjected to lateral thrust, the profile being punched is also subjected to a reaction force, resulting in a large warping force when punching the profile, which affects the safety of operation.

Design of profile punching die

In view of these characteristics of profile punching die processing, when designing the profile punching die, the influence of the lateral force of punching should be fully considered, and the influence of this lateral force should be controlled or eliminated as much as possible, and the measures usually taken are: to set the block for the workpiece and the convex die (generally placed on the concave die, the form and position of the block should be considered in conjunction with the shape of the punching workpiece and the die structure, so as to effectively offset the influence of the lateral force of shearing) Or partially lengthen the length of the non-working edge of the die, so that before punching, the cut-off die and the stopper are tightly attached first, or the die is tightly attached to the concave die at the lengthened part, so as to offset the offset force generated by the cut-off and ensure the life of the die and the quality of the cut-off workpiece.

In order to prevent the possible warping of the profile when punching and cutting, which will affect the quality of punching and the safety of the operator. The Pre-pressing and unloading devices of the press plate are installed in the die.

In order to control or eliminate the influence of lateral force during profile punching, the die usually adopts a closed structure, so that the lateral force on the cutting knife is better balanced in the closed structure and the tendency of profile warping during punching is reduced.

Commonly used profile punching die structure

The following figure shows the commonly used angle cutting die in production. In order to prevent the angle from warping when cutting, the pre-pressure and unloading of the pressure plate are made of spring and rubber to ensure the stability and safety of operation. The upper and lower die are guided by guide pillars, and the upper and lower cutting knives are blocked to bear the lateral thrust.

1-Rubber; 2-Spring; 3-Upper platen; 4-Lower cutting knife pressing screw;

5-Bracket; 6-Locating screw; 7-Support column; 8-Press plate;

9-Lower press plate; 10-Lower cutting knife; 11-Bracket; 12-Upper cutting knife

When working, the blank is sent to the positioning screw 6 along the V-shaped groove on the bracket 11 and the lower pressure plate 9. When the upper die is going down, the upper-pressure plate 3 and the lower cutting knife 10 and the lower pressure plate 9 and the upper cutting knife 12 clamps the blank respectively, and the upper cutting knife 12 and the lower cutting knife 10 complete the cutting of the angle steel together.

The upper cutting knife 12 and the lower cutting knife 10 working edge angle are taken 90°, cut off from both sides gradually cut off, so that the punching force is reduced. The lower cutting knife 10 is the symmetrical design, single-sided edge wear, can be turned 180°use. In the angle steel type material cut off die design, should ensure that the profile and concave die fit, that is, the concave cavity and the profile angle is the same, the convex die containing angle than the profile containing angle, as shown in the following figure (a), (b), similarly, the U-shaped material cut off, should also ensure that the concave cavity and the profile angle is the same, but the convex die containing angle slightly less than 90°[see the following figure (c)], in order to reduce the cutting force and improve the section quality.

The following figure is another structure of U-shaped cutting die, mainly used for the material thicker (> 6 mm) and the cutting surface has higher requirements for the cutting pieces. When working, the upper mold descends, first by the two-disc knife 2 will channel steel on both sides of the V-shaped groove 2 ~ 3 mm deep, the upper mold continues to descend, by the upper edge 1 and lower edge 3 will cut it all.

1-Upper edge; 2-Disc edge; 3-Lower edge

The following figure shows the structure of angle strike cutting die.

1 -Upper die; 2 – Oil cup; 3 – Upper cover plate; 4 – Left lower blade; 5,9,10 – Spacer;

6 – Right lower blade; 7 – Guide plate; 8 – Upper blade; 11 – Die holder;

12 – Lower die; 13 -Lower template

Before working on this die, the hammerhead should be installed in the corresponding die shank hole of the press slider. When working, put the angle steel into the V-shaped groove, and as the press slider goes down, the hammerhead strikes the upper die 1, and the upper blade 8 installed on it then goes down, and when it goes down, it cuts with the lower blade on the lower die 12, and the angle steel can be cut off.

Angle steel of different thicknesses can be cut. Cutting the thickness of 6mm or less angle steel, the upper and lower blades between the cutting gap of 0.3 ~ 0.4 mm, cutting greater than 6 mm thickness of angle steel, the upper and lower blades between the cutting gap of 0.5 ~ 1.0 mm.

Similarly, the profile can also be completed by die punching. There are two general processing methods for profile punching, namely cutting and end cutting, but no matter what method is used, the processing is done by clamping and then punching. Therefore, the design of the die should be completed by clamping the profile by the inner and outer concave die first and then cutting by the convex die. The following figure shows the structure of the profile cutting die.

The figure below shows the end cutting die of the square tube profile, which can finish the end cutting off the square tube profile and the trimming of square box-shaped parts at one time. When working, the profile is mounted on the mandrel 4, and when the upper die goes down, slider 3 is pushed to the right by the left-slanting wedge 6, and the left half of the profile is cut by its V-shaped knife edge 5, then the right slanting wedge 6 pushes the V-shaped knife edge on the right slider to cut the other half of the profile, at which time the left-slanting wedge is disengaged from the contact and pulled to the original position by the spring 1. The original position of slider 3 is positioned by stopper 2. After the upper die goes up, the profile is withdrawn from the mandrel 4 by hand pressing the exit pin 7. The knife-blade 5 always makes a guided movement between pillar 8 and mandrel 4.

1 – Spring; 2 – Stopper; 3 – Slider; 4 – Arbor; 5 – V-shaped knife edge

6-Slanting wedge; 7-Exit pin; 8-Pillar

The figure (b) below shows the percussion cutting die used to cut the profile shown in figure (a).

1 – Platen; 2 – Fixed blade; 3 – Positioning clip; 4 – Support

5-Frame; 6-Cover; 7-Active blade; 8-Die handle

When working, the profile is first placed inside the fixed blade 2 and the movable blade 7, and the positioning block 3 controls length of the cut profile. With the downward movement of the press slide, the die handle 8 pushes the movable blade 7 downward during the working stroke of the press, so that it rubs against the fixed blade 2 and cuts the profile.

No matter what kind of punching method is used, the design of the profile punching die still focuses on controlling or eliminating the possible deformation caused by the punching lateral force and the impact on the punching accuracy. Therefore, the structure of the profile punching die and the measures it takes are also applicable to the design of the profile punching die. The profile cross-section is generally more complex than that of the profile, and for profiles with different cross-sectional structures, the shape of the die should be properly designed to ensure the cutting quality. The figure below shows the recommended die shapes for punching profiles with different cross-sections.

The main failure mechanism on punches and dies

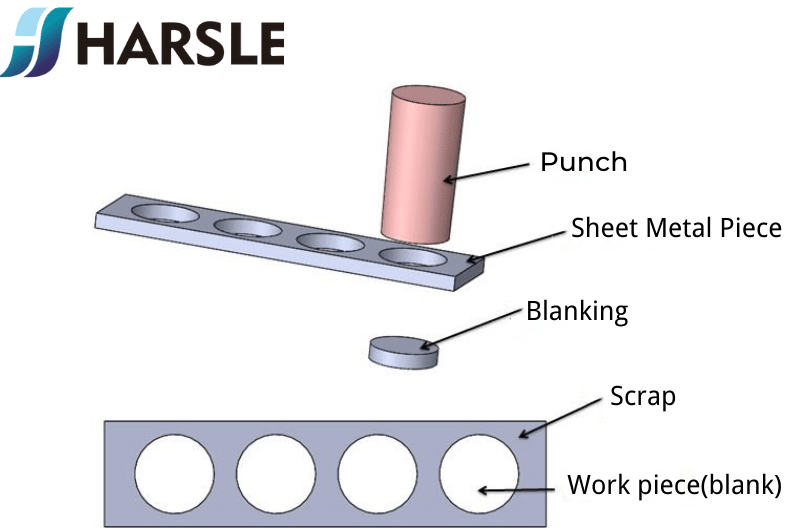

Blanking is a metal production process, during which a metal workpiece is removed from the primary metal strip or sheet when it is punched. The material that is removed is the new metal workpiece or blank.The cut surface of a cut band created with a conventional metal punching process is partially angled and has a rough appearance in the fracture zone of the cut.

During the punching/blanking operation, the working parts (punches and dies) behavior depends on the working material (thickness, tensile strengths, yield strengths) and the tool steel ability to cope with the stresses that arise on the cutting edges.

Due to the pressure on the blanking edge of the punch and the die, the complex stress distribution is achieved during blanking. After plasticizing the material, depending on the method of the process, different geometry of the intersection surface and burr size can be obtained. In the case of deformation of the sheet material, the punching force causes the tools to be loaded. The greatest pressures are close to the tool’s cutting edges. The pressure of the punched material on the punch surface and the friction cause intensive tool wear. The vector of reaction forces for the tools is inversely directed to the working movement of the punch. This causes a bending of the sheet, which results in the lateral action of forces. The clearance between the tool edges determines the value and orientation of the contact force.

1. Plastic deformation

The permanent deformation occurs when the compression stress exceed the compressive yield strength of the tool steel. Hardness is the critical parameter.

Chipping and total breakage: Both cracks initiation and cracks growth are deleted by high tool steel ductility/toughness. The very fine and homogeneous Powder Metallurgy tool steel microstructure gives the tools a good level of impact strength and fatigue limit in case of brittle behavior.

2. Abrasive wear

Abrasion appears on the sliding contacts between the tool and the working material. Abrasive wear is caused by hard particles in contact with the tool surface. The critical tool steel properties are hardness, high volume of carbides and high hardness of the carbides.

3. Galling and adhesive wear

Both galling and adhesive wear is created by compressive stresses and sliding contact resulting in heavy friction and locally high temperature which can lead to micro-weld spots that destroy the surface quality of the tool. Then, due to the working stresses, parts of the stick material are pulled out of the tool surface by the work material. The critical parameters are roughness, friction coefficient, toughness/ductility, and hardness. The tool steel grade has a big influence and Powder Metallurgy tool steels can offer a suitable solution, together with surface coating in order to optimize the sliding properties.

Moreover, when punching or blanking advanced high-strength sheet metals, stresses and shock waves increase a lot on the cutting edges of the tools. In such cases, the use of conventional tools steels (D2 and M2 types) is not recommended due to the too low fatigue strength/impact strength level, which leads to early cracks and total breakage of punches and dies. Chipping and cracking are probably the most detrimental failure mechanism that can occur in the production plant.

With the powder metallurgy process, the microstructure of the ASP tool steels is much refined with a very even distribution of finer primary carbides. This results in an improved combination of toughness, strength, and hardness in comparison to conventional tool steels.

The blanking experiment

The hooks were cut in a sheet with a thickness of t = 0.5 mm. The sheet was made of C45 (1.0503) non-alloy carbon steel for thermal improvement. Table 1 shows the chemical composition and table 2 shows the mechanical properties after heat treatment.

Chemical composition(average), %

| C | Mn | P | Cr | Si | S | Ni | Mo | Fe |

| 0.48 | 0.73 | 0.011 | 0.09 | 0.35 | 0.01 | 0.02 | 0.002 | other |

Mechanical properties of hardened steel C45

| Yield Strength Re [MPa] | Tensile Strength Rm [MPa] | Elongation A5 [%] | Hardness HRC |

| 335 | 2285 | 30 | 55 |

The blanking process was carried out with a punch with a 12° sloped face. The most important dimensions of the blanking punch are presented in figure below. During the tests, the punch movement was 50 strokes/min.

The tests were carried out for three values of punching clearance (clearance (C)/sheet thickness (t)): 5%, 10%, 15% (Figure a). The stroke of the punch was set so as to obtain a penetration depth H = 1.2 mm (Figure b).

(a)Outline of the die hole and punch; (b) Clearance

(C) Blanking depth (H) Punch in the sheet

Sheet metal blanking with high strength properties requires, for punches, the selection of a material with good strength and relatively high resistance to abrasive and adhesive wear. In the case of short series of blanked products, the economics of the material used for the tools is important. The punch was made of K340 Isodur tool steel. Steel with a content of ~8% chromium is produced in the technology of electroslag remelting process (ESR).This steel is characterized by, among other things, high adhesive resistance to wear and compressive strength. Thanks to the micro-addition of aluminum, the oxide passivation system is improved, where passivation of the surface takes place.

After passivation, this layer reduces the tendency of particles of punched material adhesion to the cutting surface of a punch. The hardness of the punch after heat treatment was 62 HRC.

I’ve learned a lot from your blog! I hope you will keep updating

Kann man das Profilschneiden auch mit der Wasserstrahltechnik machen? Das wäre total praktisch. Denn beim Wasserstrahl entsteht keine hohe Temperatur.